Harbin, a charming ice city known as the “eldest son of the Republic”, is an important industrial town in North

China on the bank of the Songhua River, which is constantly flowing and magnificent. Here, there is an

enterprise with the dream of letting China's bearing industry lead the world--Harbin AVIC Bearing Co., Ltd.!

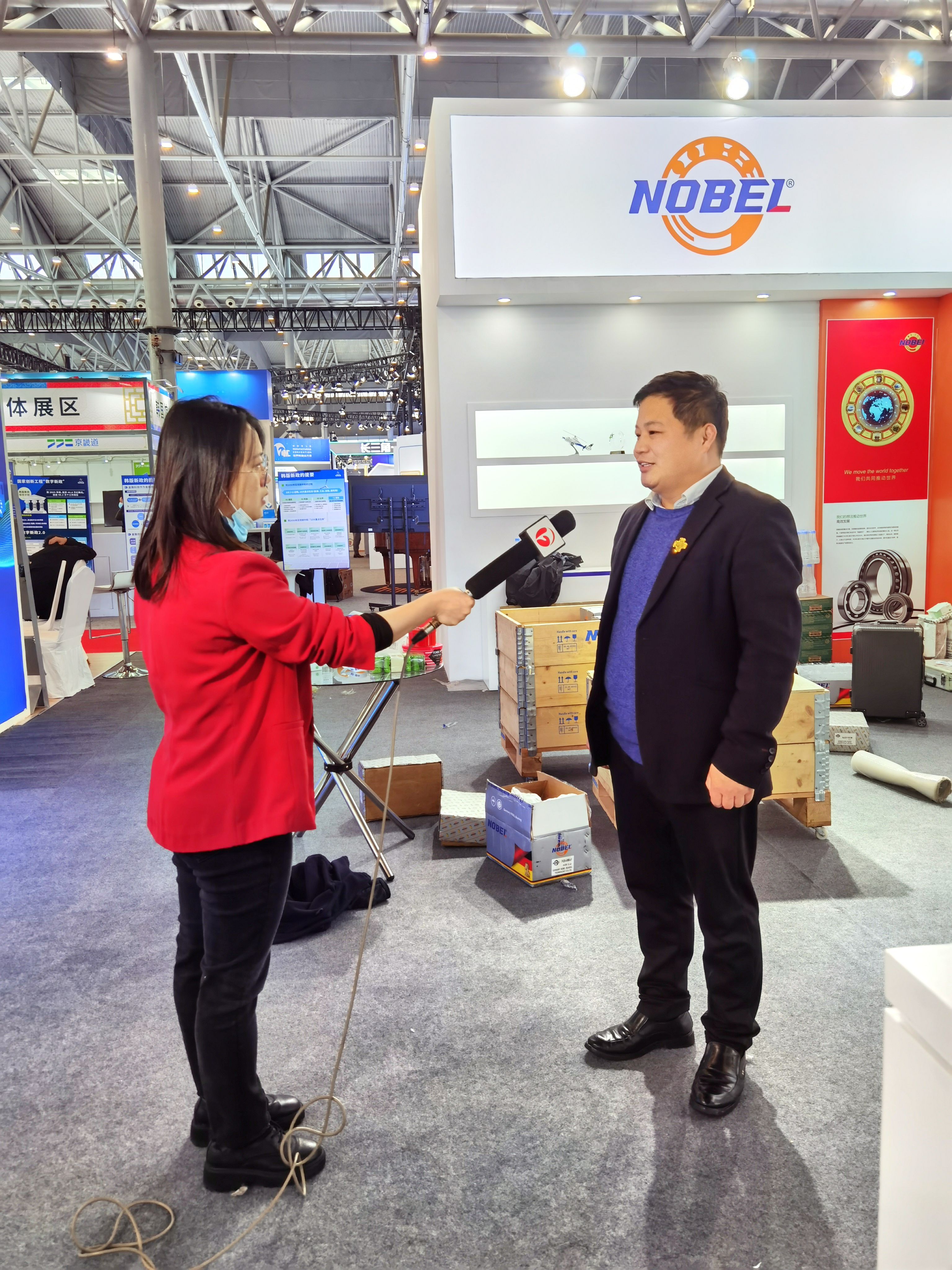

AVIC has an international pedigree. Tracing back to the source, the company was established in

cooperation with the invisible champion of the European bearing industry, Nobel Bearing Technology Co.,

Ltd., with a registered capital of 51.88 million yuan. The technical level has been leading the industry from the

beginning. The company focuses on customer needs and provides solutions for customers from all walks of

life on a global scale. The company has advanced manufacturing technology, experienced engineers,

continuous product research and development capabilities, and a series of unremitting efforts have made us

an expert in bearing innovation. The company's special advantages are: 1. Carrying out special bearing

research and development work according to the individual needs of customers; 2. Coordinating, checking

and implementing specific projects with customers; 3. Optimizing the actual service life, strength test and

application results of the products. In short, the company will do its best to integrate the essence of the

international bearing industry to create high-quality bearings that belong to the Chinese people.

AVIC has strong scientific research backing. The company is a member unit of China Aerospace Science

and Technology Industry, China Bearing Industry Association, China Chamber of Commerce for import and

Export of Machinery and Electronic Products, China Agricultural Machinery Circulation Association, China

Construction Machinery Association and other organizations. At the same time, the company is also a key

foreign trade export enterprise in Harbin, and 50% of its products are exported abroad. The company

conducts economic and technical cooperation with Harbin Institute of Technology, Harbin Institute of

Engineering, Bearing Research Institute and other scientific research institutes, and continues to increase

scientific research investment. As of this year, the company has obtained nearly 100 invention patents and

dozens of utility model patents, forming a strong scientific and technological reserve.

AVIC has a team that can recruit and fight well. The company has gathered a large number of elites in the

industry and formed an excellent team with superb professional standards and reasonable talent structure.

The company implements the distribution system of "work more, get better, get more innovation, and get

more innovation" and the promotion system of "must be tested for every promotion", carry out scientific and

reasonable performance appraisal management, and release the majestic power of executive

entrepreneurship. The personnel structure, department configuration, and management model are all in line

with international enterprises, and a management system with ERP as the core and a rapid response

processing system integrating quality monitoring, process monitoring and customer complaints have been

established. Fast and efficient after-sales service eliminates customers worries for the future.

AVIC has high-standard quality certification and processes. The company has obtained ISO9001 quality

management system certification, TS16949 quality management system certification, ISO14001

environmental management system certification and ISO45001 occupational health and safety management

system certification. The company insists on selecting high-quality raw materials, strictly implementing

process control and quality monitoring standards, ensuring a high degree of consistency between product

performance and quality, and providing customers with reliable products. At the same time, the company

continuously improves product performance by optimizing product structure and improving process flow to

meet the higher standards of customers.

AVIC has the world's top precision intelligent manufacturing equipment. The company vigorously

introduces various types of equipment in the leading industry, from high-speed upsetting of bearing steel,

automatic high-precision turning and milling, cryogenic quenching, unitized automatic constant temperature

grinding, and the formation of a complete industrial chain of intelligent assembly will provide AVIC The core

hardware data processing of the bearing has achieved a stable and reliable foundation. It has nearly 1,000

sets (sets) of bearing production and testing equipment. Advanced finishing equipment includes: double end

grinder, CNC raceway grinder, data internal grinder, automatic bearing assembly production line, tapered

roller automated production line, etc., demanding fiber and nanometer, forging extremely sophisticated

bearing products; testing equipment includes: surface Profilometers, metallographic microscopes, surface

roughness meters, roundness meters, projectors, projection universal length measuring instruments, bearing

vibration measuring instruments, strictly adhere to the original intention of quality, and create first-class quality

that can withstand the test of market and time.

AVIC has many national operation centers. According to the development layout and market demand, the

company has established a foreign trade center, a warehousing logistics distribution center in Shenyang

branch, Nobel Technology (Shenyang) Co., Ltd., which is promoted and sold under the German NOBEL

Nobel brand, and East China Operation Center Nobel Bearings (Shanghai) Co., Ltd., Southern Operations

Center SKF (Guangzhou) Bearing Co., Ltd. (SKFGZ brand bearings, lubricants). Inherit the spirit of

craftsmanship, pursue better quality and better performance; open up the boundaries of scientific research,

make unremitting progress, and create a well-known Chinese bearing brand-AVIC.